Bag Styles

To be used with or without vacuum sealing

4.3 MIL MYLAR POUCHES

Size 1

10"x14" - come 1500 bags/ctn

Size 2

10"x16" - come 1100 bags/ctn

Size 3

20"x30" - come 200 bags/ctn

Size 8

8"x8" - come 2200 bags/ctn

5.25 MIL MYLAR POUCHES WITH A ZIPLOCK 2" FROM THE EDGE OF ONE OPENING

D1

8"X10" - come1400 bags/ctn

D2

10"X16" - come 700 bags/ctn

D3

20"x30" - come 200 bags/ctn

Customizable

These pouches are customizable to your business needs

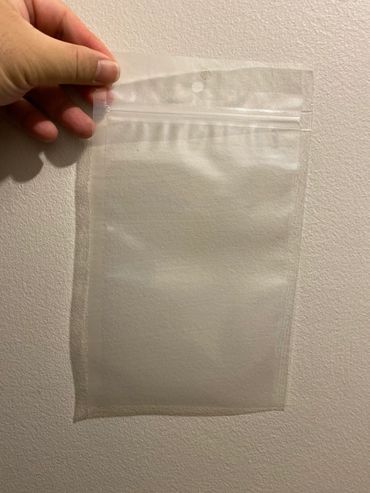

clear bags TO BE USED WITH OR WITHOUT VACUUM SEALING

4.3 MIL MYLAR POUCHES WITH A ZIPLOCK 2" FROM THE EDGE OF ONE OPENING

10x6

1000 bags/ctn

12x6

1000 bags/ctn

Customizable

These pouches are customizable to your business needs

Add a footnote if this applies to your business

Photo Gallery

Mylar bags

What is Mylar?

BoPET (Biaxially-oriented polyethylene terephthalate) is a polyester film made from stretched polyethylene terephthalate (PET) and is used for its high tensile strength, chemical and dimensional stability, transparency, reflectivity, gas and aroma barrier properties and electrical insulation.

A variety of companies manufacture boPET and other polyester films under different brand names. In the US and Britain, the most well-known trade names are Mylar, Melinex and Hostaphan.

To be honest, Mylar isn’t any better or worse than many other sealant layers, such as branded films of LLDPE. It is just the most widely known.

Wait, your Mylar bags aren’t clear; what’s up?

The polyester film is combined with an aluminum foil layer and in some cases another sealant layer of LLDPE (Linear Low-Density Polyethylene); this allows for good heat-sealing, UV protection, incredibly low odor transmission, and high puncture resistance. Aluminum foil is the best barrier layer available in food storage packaging today.

How do I seal Mylar bags?

Mylar can be sealed with a variety of devices, including a hot jaw sealer, clothes iron, or hair straightener.

I can see pinholes of light coming through the Mylar bag, why is that?

All foil structure Mylar bags will have small pinholes in the foil layer. There is a measurement, ‘Pinholes per meter squared’, that is part of the specification of foil bags. Pinholes affect all foil structures, from a thin 2.5mil bag to the thickest 7-8 mil bags. The other transparent layers of the bag keep the integrity of these bags, and it is only very rarely (less than 1/100th of 1%) an actual ‘pinhole puncture’. Plus, some pinholes are so small they are invisible to the naked eye, but they are still there.

Why don’t my bags get hard when I use an oxygen absorber?

This is our third most common question. While there will often be compression of the Mylar bag after sealing due to the oxygen absorber, an absorber is only removing the 20% of the atmosphere in the bag that is oxygen, leaving the 80% that is nitrogen intact.

There is also a specific density of food to headspace (air) that is also required. As I mentioned above, you could put 100 oxygen absorbers into a small Mylar bag and it won’t contract. Obviously there is plenty of absorption capacity, but the packets themselves don’t have the required density/shape to allow contraction. In terms of headspace, as little as .1 liters of air can cause extreme contraction in one bag and mild contraction in another.

Please note also that 3.5 mil bags tend to show their compression a lot more, down to the shape of a kernel of wheat. 5 mil bags may ‘feel’ tight but show compression much less. A 7 or 7.5 mil bag may simply ‘feel’ compressed without much visible sign.

A tip: when sealing alufoil bags make sure you remove as much of the ‘headspace’ as you can; this is the area at the top of the bag you seal. Even a little headspace can use up much of the power of the oxygen absorber.

Copyright © 2024 OxyFree - All Rights Reserved.

Powered by GoDaddy

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.